Here’s a little-known problem that can afflict clay pipe makers who leave their greenware outside.

Mud dauber wasps may decide to make their nests inside the stems of unfired pipes.

My wheel is on a covered porch at the back of our house, and I have a shelving system that is basically open to the outdoors, though sheltered from rain and wind. Ware gets put here to complete drying, and eventually moves into the kiln room when it’s ready to be fired. But apparently wasps find the inside bore of a pipestem to be just the right size for a nest.

These simple little pipes stayed on the shelves for a week or two before going to the kiln. Somehow I failed to notice that a wasp had built her nest in the stem of one of them. I bisque-fired the piece, and still didn’t notice. I glazed it, fired it, and photographed it, all without noticing that a nest had completely blocked it up.

When I finally did notice, I was astonished.

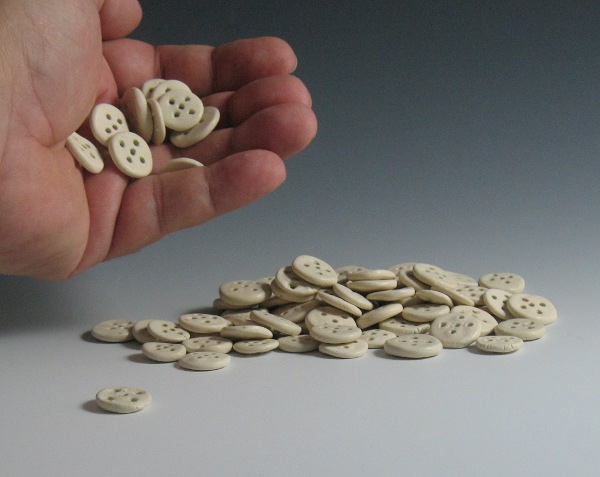

Mud dauber wasps gather up clay from various sources and use it to build their nests. When a colony of such wasps has built a large nest, you can actually fire it and turn it into a ceramic object, which makes an interesting conversation piece for the coffee table.

Had the wasp gotten her clay from my porcelain scraps, which are omnipresent in my studio, the blockage probably would have been irreparable. But I took a piece of baling wire and forced it into the stem, clearing out much of the blockage. But the pipe still wouldn’t draw. A careful examination revealed that the wasp had built another nest at the bowl end of the stem. Evidently she flew into the bowl and around the corner into the stem. This blockage was sturdier than the first, and eventually I had to pound a deck screw into the nest through the carb hole in the side of the pipe. That did the trick, and the pipe draws very well now.

I don’t know what if any special qualities a pipe that was intended to be the home of wasp babies might have, but it’s an interesting overlap between the natural world and the world of ceramic art.